Allows a significant productivity improvement.

Automates tile packing operations.

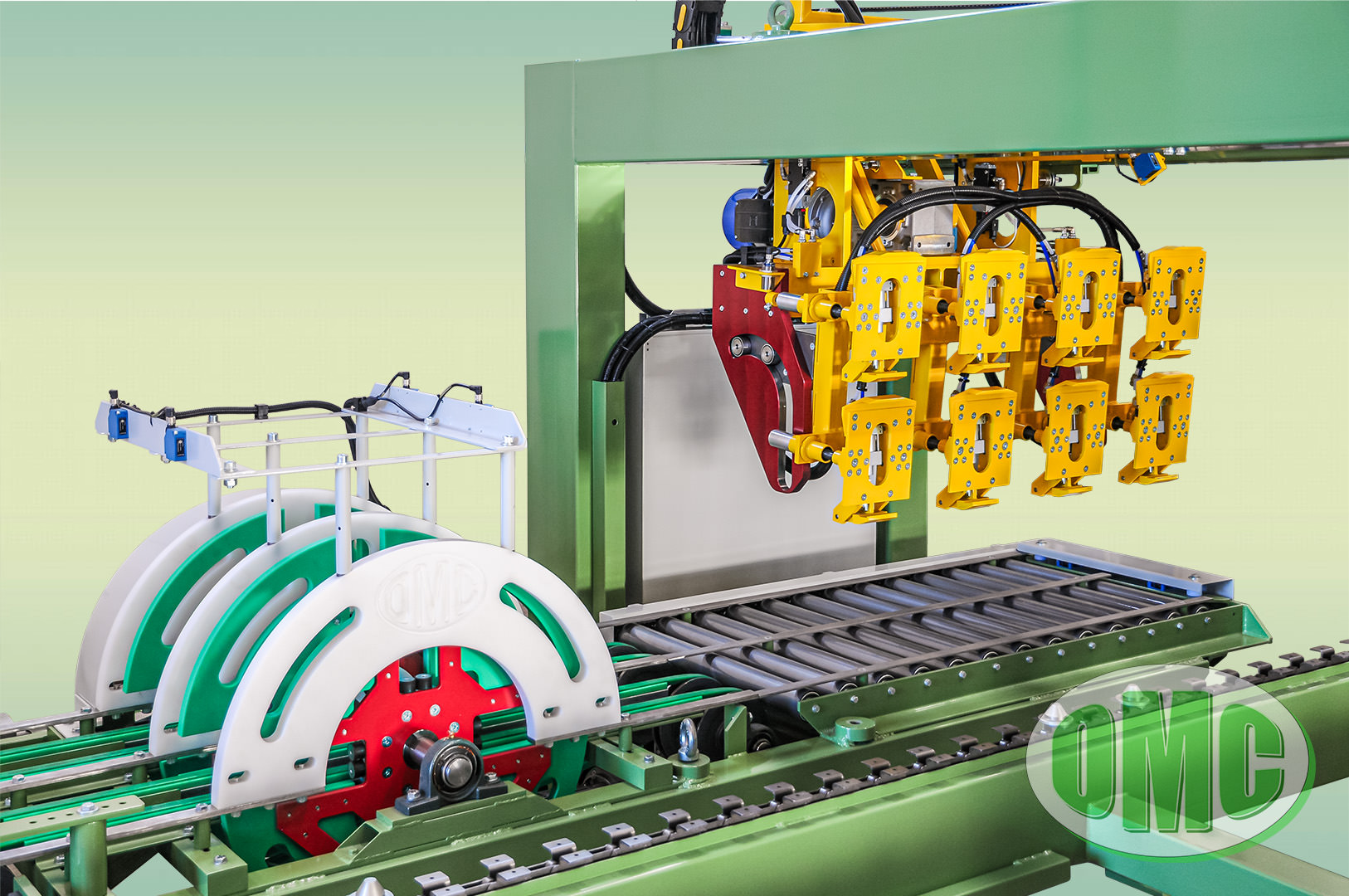

The Automatic Palletizing Conveyor Mod. OM50/P automatically stores and packs grinded and polished tiles, taking them at the exit of the polishing machine; a special pneumatic vacuum system picks up the tile, moves and deposits them on wooden pallets (storage can be in simple rows or superimposed rows).

A conveyor synchronizes and moves the wooden pallets, stored in a special vertical warehouse.

Electric Control Panel with programmable PLC logic and Touch-Screen panel for the management and supervision of machine.

Technical Features

Automatic robotic system for tiles pick-up at grinding machine exit and subsequent packing on wooden palletst:

The production capacity is about:

- 35 pieces per minute for sizes 25×25 and 30×30;

- 8 pieces per minute for sizes 40×40 and 50×50;

The overall weight is about 3.200 Kg;

The installed power is 13,5 kW.