Allows a significant productivity improvement.

Reduction of manpower, rationalization of production costs.

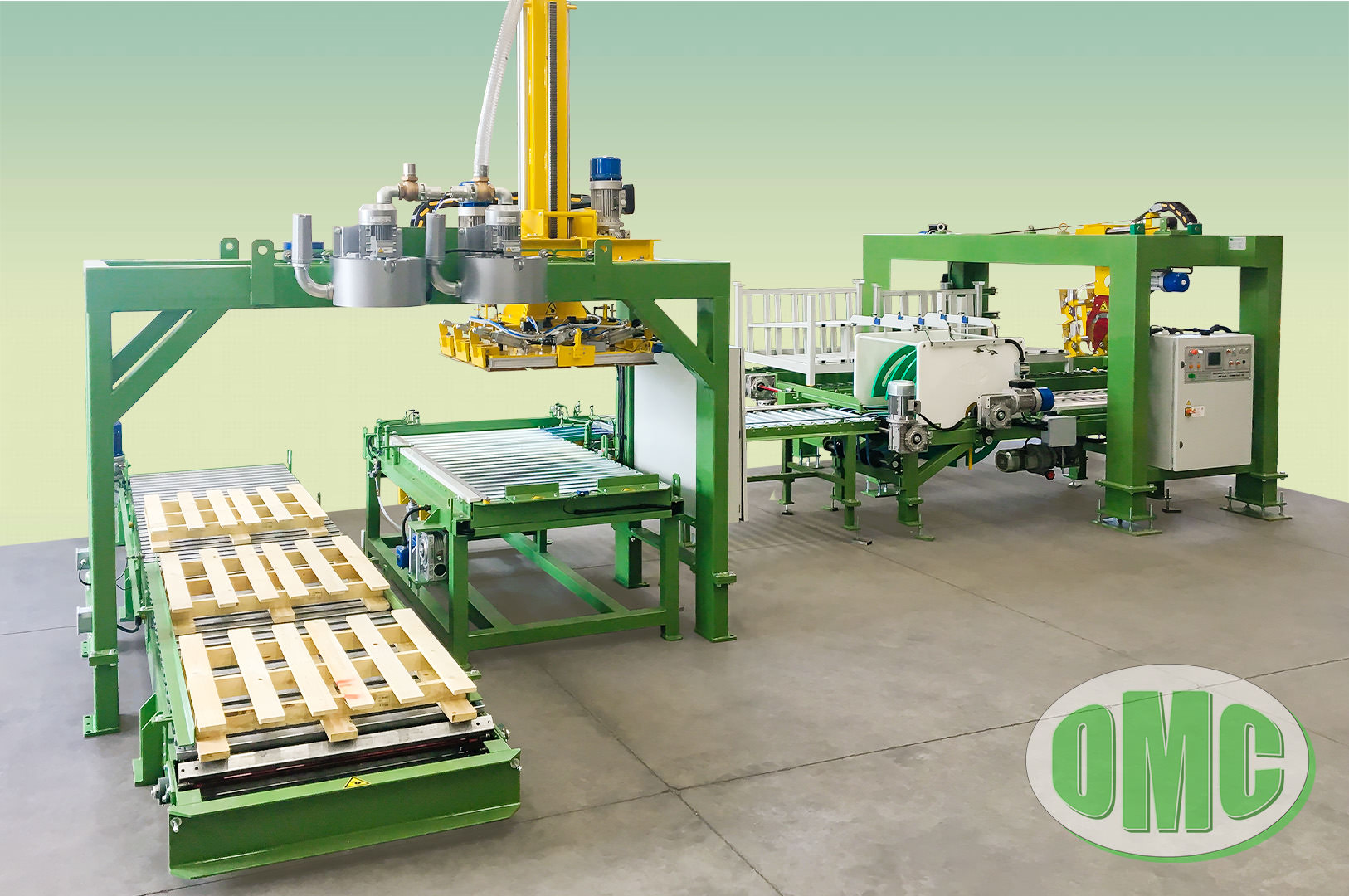

Specifically built to be used combined with our Semi-Automatic Press Mod. OM200-R and our Automatic Rotational Press Mod. OM240-R, this robot allows to automate demoulding, collection and storing in metallic containers of fresh tiles, with a significant improvement in productivity and reducing the manpower needed, resulting in rationalization of production and management costs.

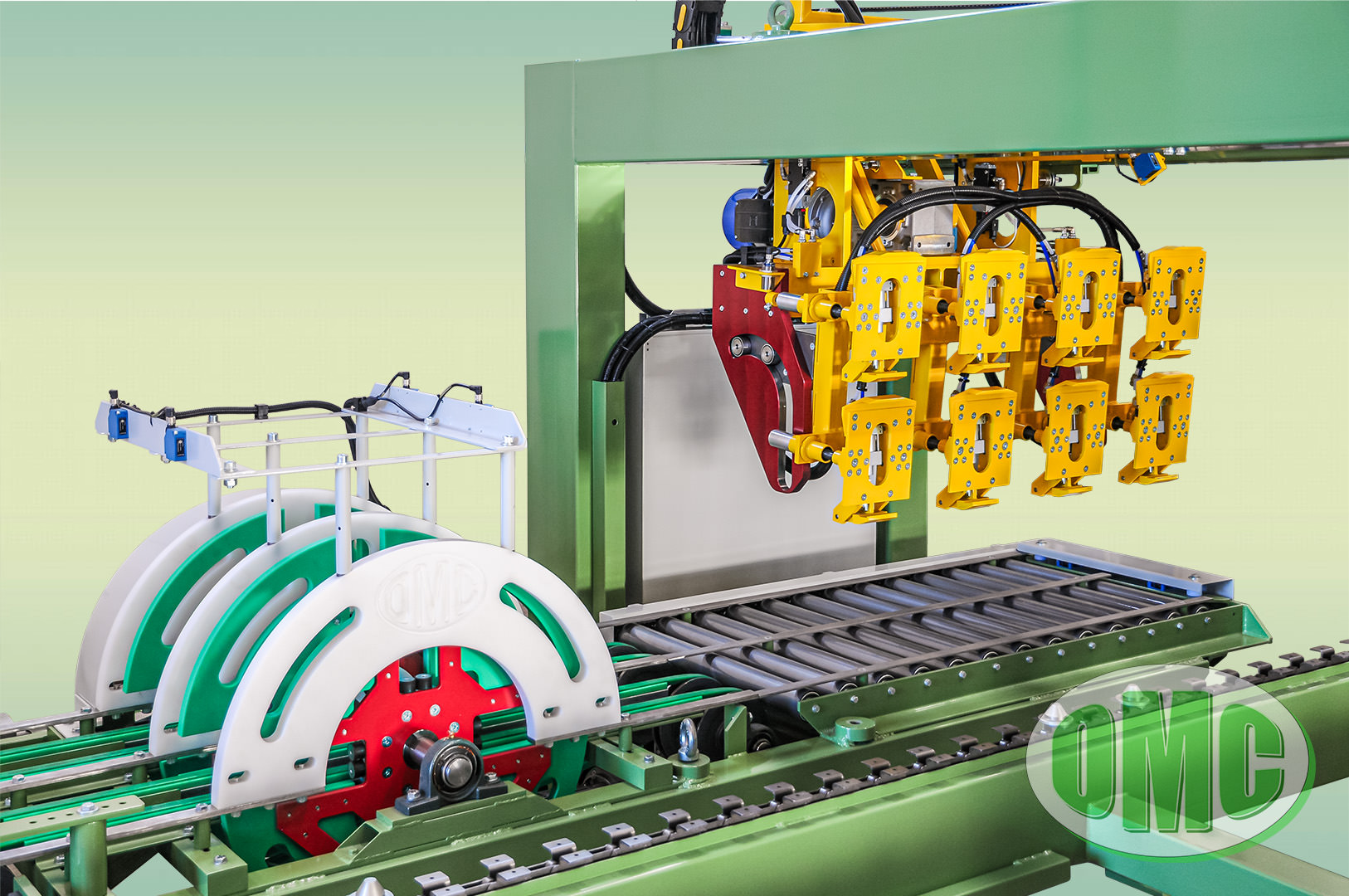

Designed with the same methodologies and innovations applied to our Automatic Tiles Handling Systems OM50 Series, this pick-up system provides with a revolutionary Aerial extraction blade, our exclusive design,to extract fresh tiles from the press, then it picks up the tiles using special iron-rubber suckers and stock them vertically inside a specially designed metallic container.

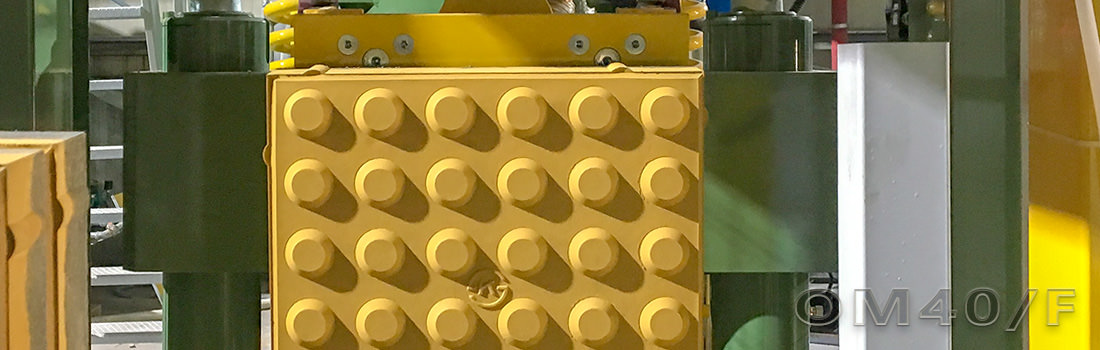

Compact and robust, the new Automatic Drawing Conveyor Mod. OM40/F brings the automation also in small industrial production and in the production of handicraft and decorative tiles.

Designed to maintain low the purchase costs, we have designed a pick-up group that can be used for both 33×33 and 40×40 sizes, changing only the iron-rubber sucker and using the same metallic container for storage.

Available both in the version with manual translator or with automatic translator for the handling and positioning of metallic containers.

Its extreme versatility allows it to be combined with all types of rotational presses available on the market, up to 5-station versions.

Equipments

Technical Features

Automated robotic system for the collection and storage of fresh tiles:

The production capacity is approximately 6 cycles per minute;

The overall weight is about 1.300 Kg;

The installed power is 3,90 kW.