Precision Mechanics

Large and equipped production departments, reliability and seriousness

OMC Costruzioni Meccaniche is specialized in precision mechanics and, in particular, in the production and assembly of semifinished and finished mechanical assemblies, including metallic carpentry, CNC mechanical processing, painting, assembly, electrical wiring and final testing.

The company, strengthened by its organizational structure and its specific skills in the production of machinery and plants as well as in the management of complete supplies of materials and works on commission, aims to provide customers with tailor-made services and take on the role by Main Contractor.

The over twenty years of experience in the industry is an additional advantage for the customer, who can count on a proven solidity, on a high management capacity and on highly qualified personnel.

Values and strengths of OMC Costruzioni Meccaniche are:

For over twenty years in the production of machinery and automatic plants sold all over the world, OMC Costruzioni Meccaniche has made its know-how and organizational structure available to support other machine manufacturers in the production of their projects, guaranteeing quality and seriousness.

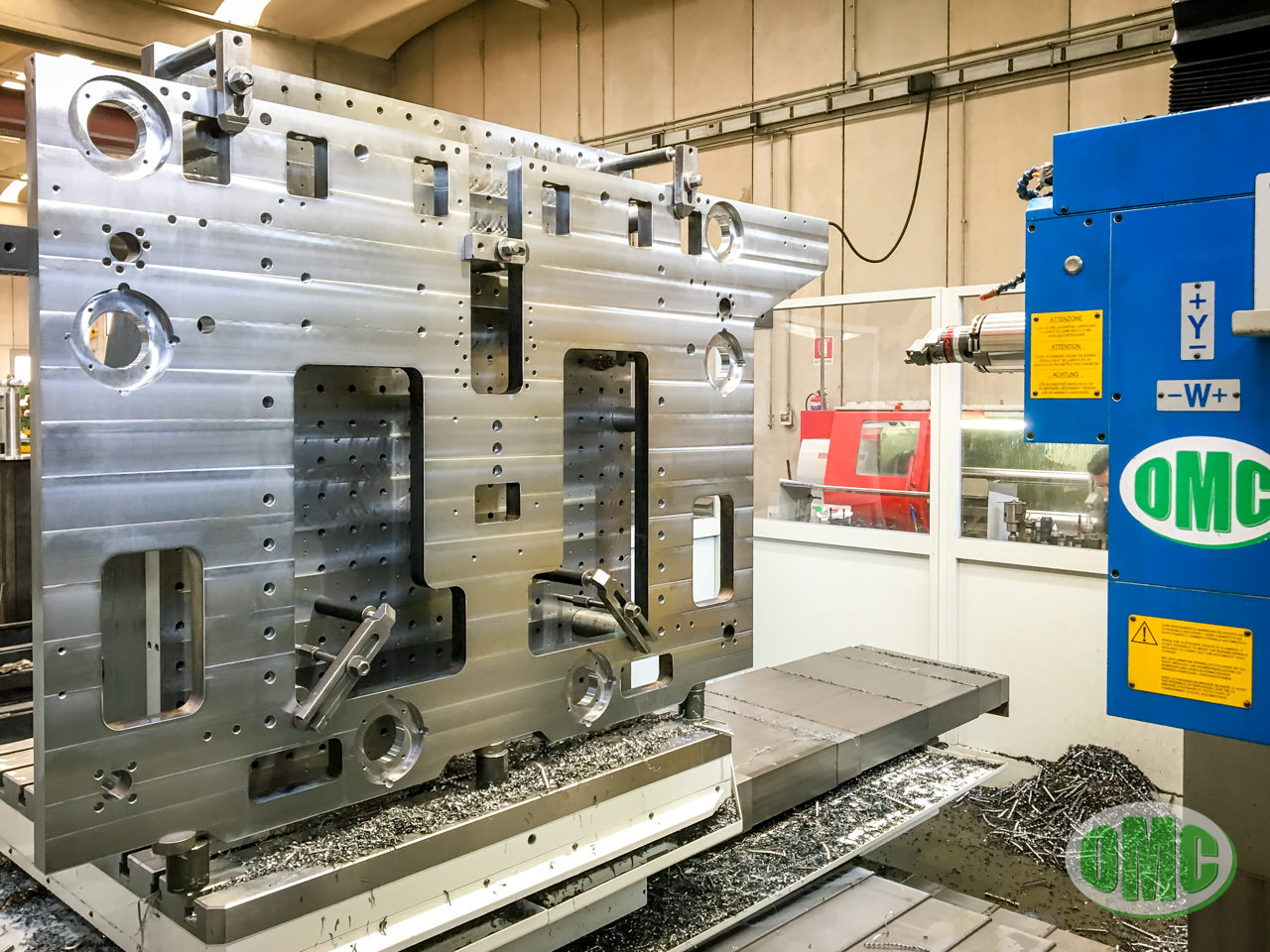

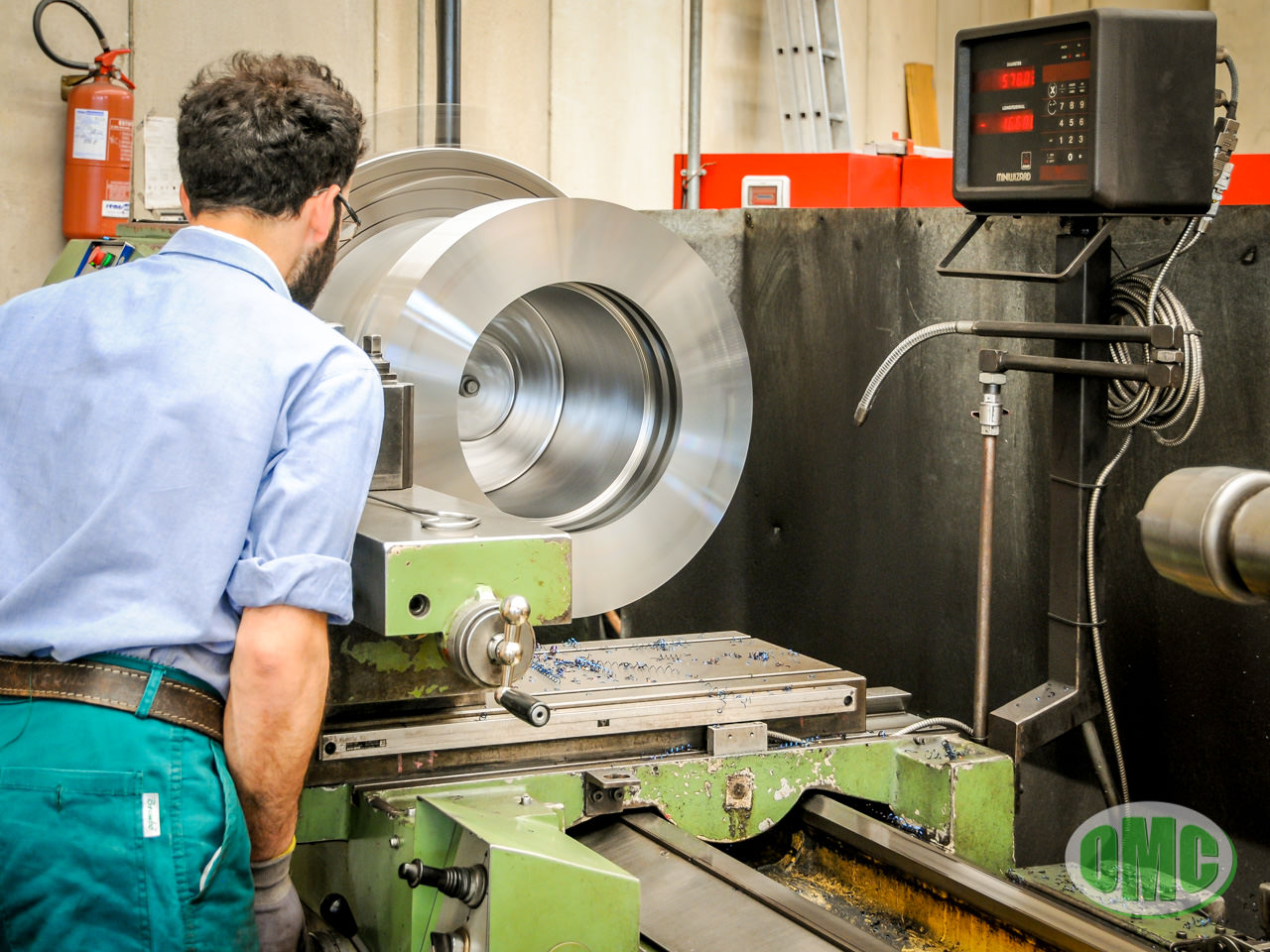

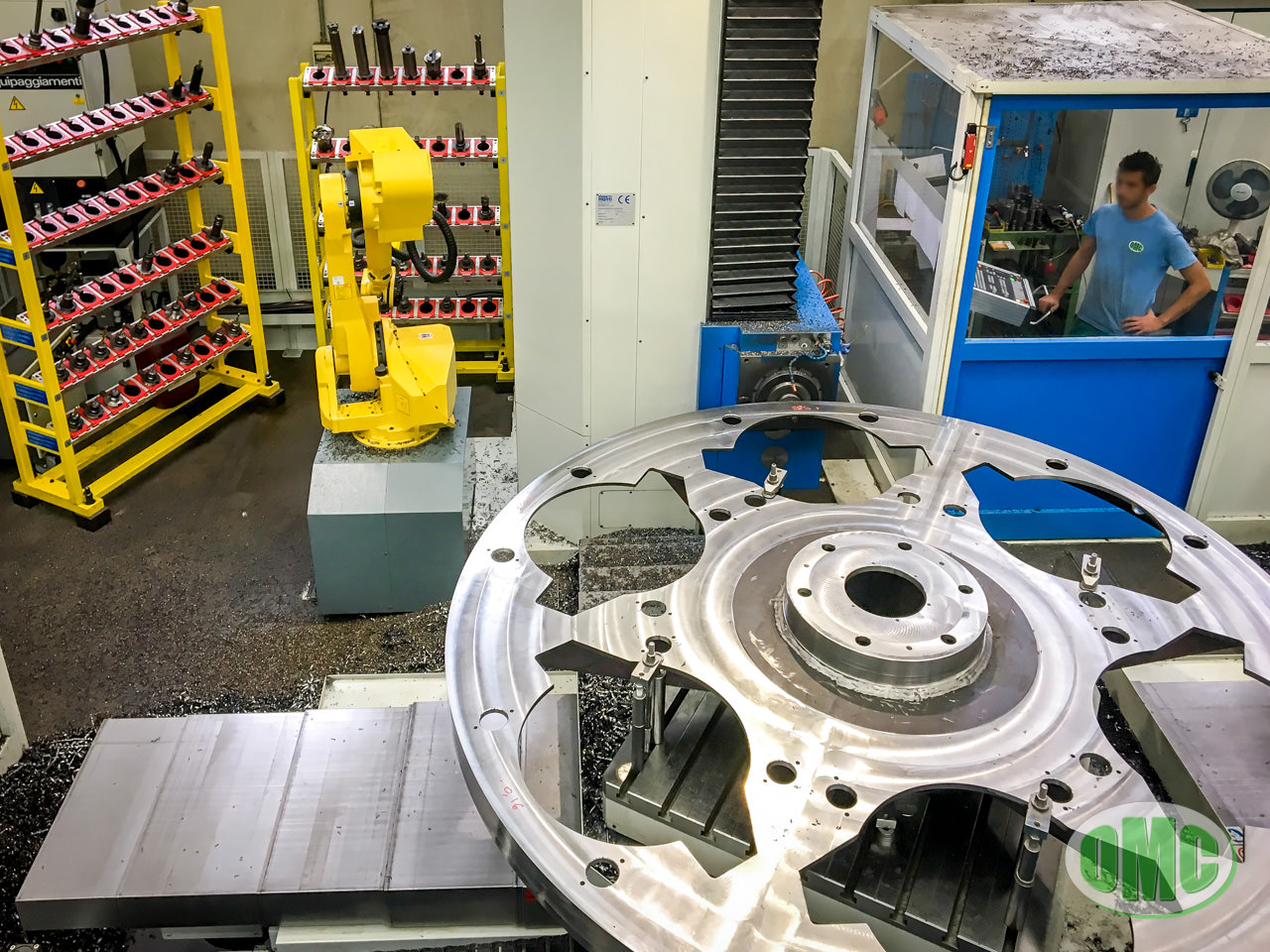

CNC Machine Tools Department

Latest Generation Machinery, 5 TONS Overhead Crane

Thanks to our large and equipped CNC Machine Tools Department, we are able to manage the production of mechanical parts, even of large dimensions, as well as serialized processing of large quantities thanks to the large space available for the storage and handling of raw materials, semifinished and finished parts.

Our CNC Machine Tools department is also equipped with:

Metallic Carpentry Department

5 TONS Overhead Crane

OMC Costruzioni Meccaniche is also equipped with a large and equipped Metallic Carpentry Department:

Painting Department

Electrostatic painting; 10 TONS Overhead crane

Our Painting Department allows us to also supply finished parts, ready for assembly, painted according to your specifications and your RAL code.

Equipped with a large suction plane and high and low pressure electrostatic painting equipment capable of guaranteeing a better final quality than the classic spray painting according to the best transfer and adhesion efficiency (even up to 90%).

On request, it is possible to paint the mechanical parts with high thickness and high passivating Epoxy Vinyl Anti-corrosive Primer, to guarantee greater durability of the painted parts even if subjected to particularly aggressive working conditions.

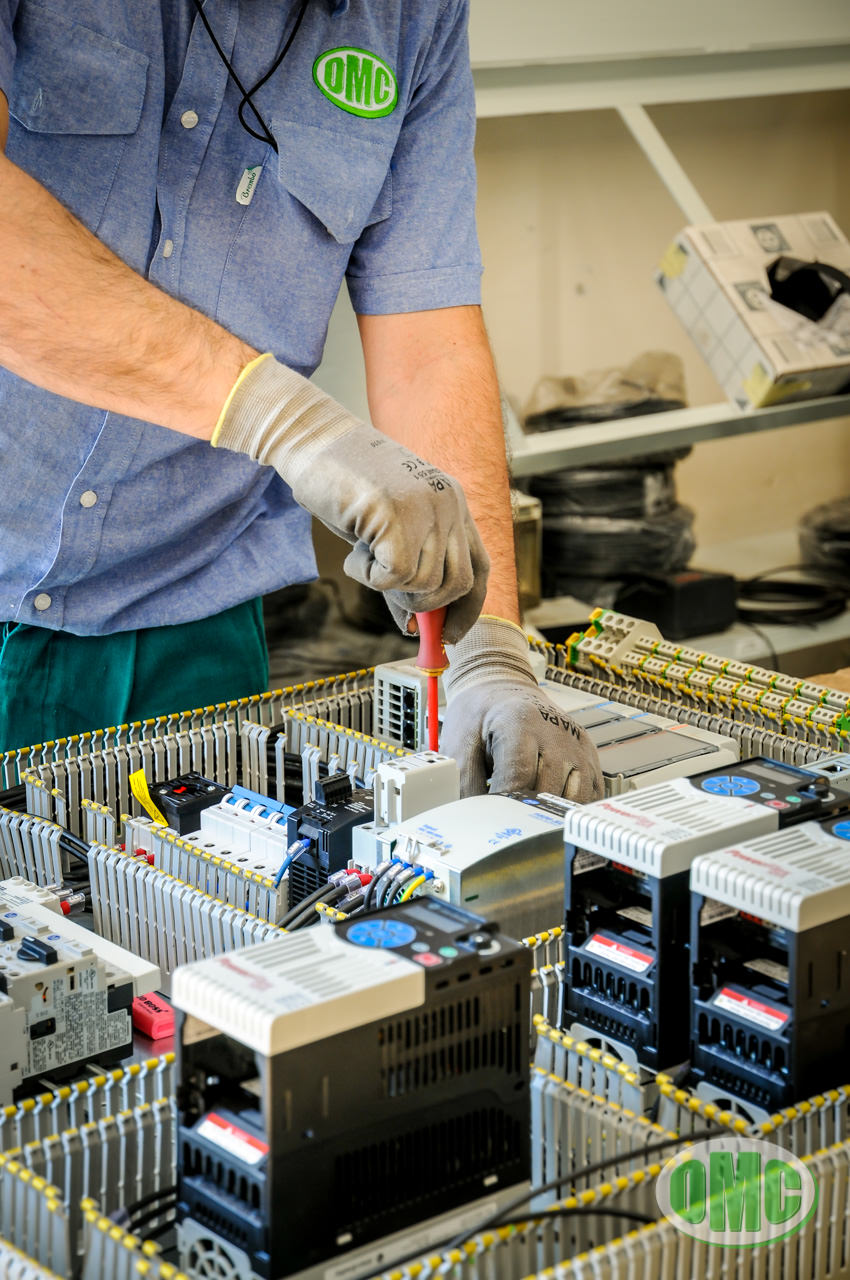

Electrical Department

Electrical design and assembly

Thanks to the internal electrical design department and its assemblers, OMC Costruzioni Meccaniche is also able to provide the asembly of electrical panels as well as the electrification of the machine.

Our over twenty years of experience as machine builders allows us to have a broad knowledge of all the components typically used in industrial automation, both electromechanical and electronic, for the construction of both the small manual control panel, up to the automation panel complete with PLC, Touch-Screen, Electronic Inverter, etc.

The components can be supplied by the customer, or managed directly by our company, based on the production order.

We are also able to manage electrical projects developed with EPLAN P8 Electric, in addition to various CAD software available on the market, we are also able to transfer the programs and settings provided by the customer to PLC, Inverter and Touch-Screen Allen-Bradley/Rockwell and, on request, on Schneider Electric and Siemens products.

Assembly Department

10 TONS Overhead Crane And 1,000 sqm Of Useful Surface

Separated from the CNC Machine Tools Department and from the Metallic Carpentry, in order to preserve the cleanliness of the machinery during assembly, there is also the department dedicated to mechanical and electrical assembly.

With 1,000 sqm of usable surface, the Assembly Department can accommodate a large quantity of finished and semi-finished parts, machine parts as well as complete machinery and plant parts, with the possibility, for the customer, of being able to also carry out tests and inspections direcly in our factory.

The availability of a 10 Tons overhead crane allows easy handling even of components with important weight and dimensions, simplifying management and loading/unloading operations, reducing time and costs.

In addition, the large external area it also allows access for large vehicles.