Allows a significant productivity improvement.

Easily fits all linear polishing machines for tiles grinding/honing.

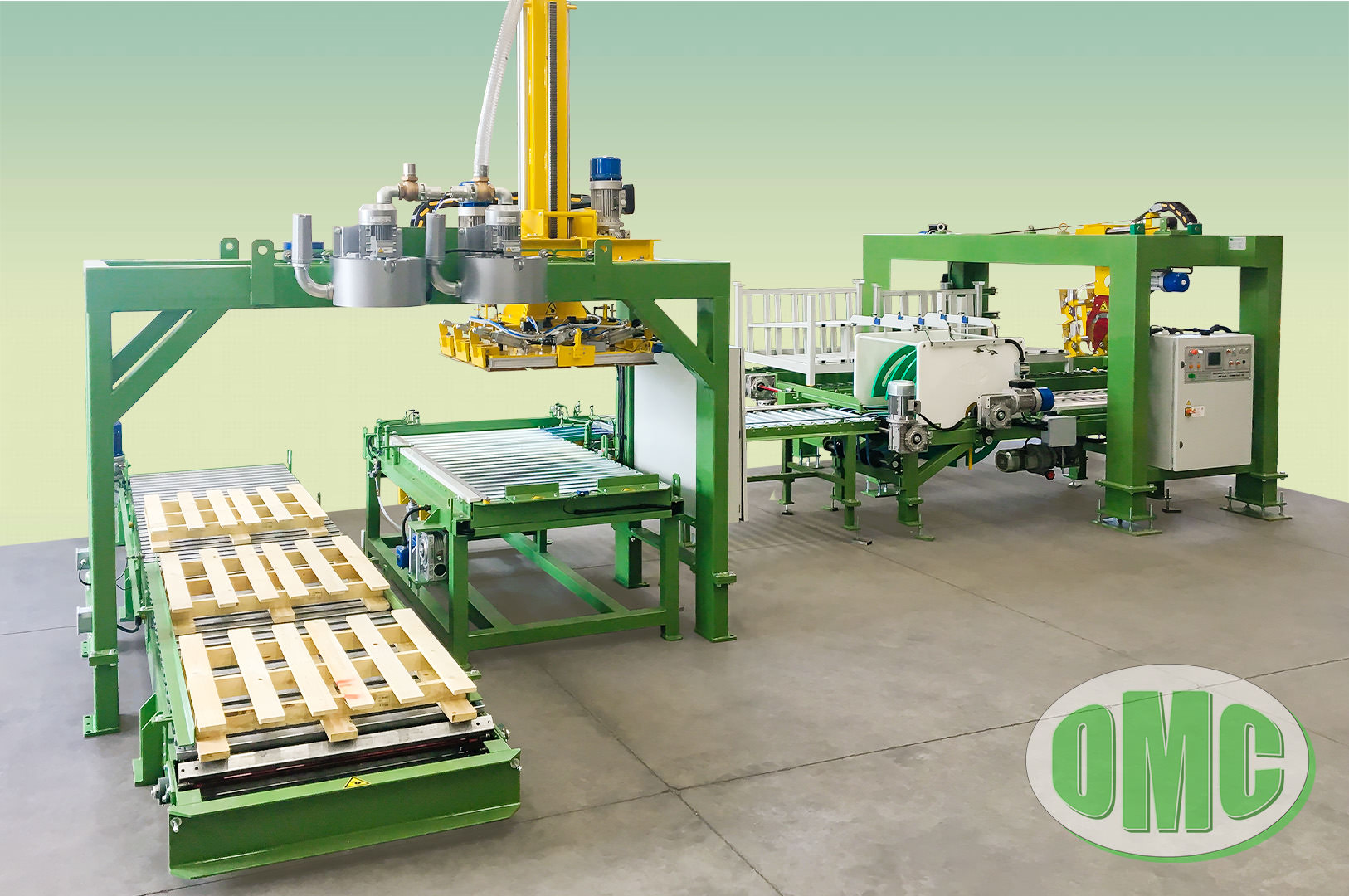

Automatic device used to unload cured tiles from the metallic containers and to feed continuously linear polishing machine.

After that tiles are collected by special mechanical pliers, pneumatically driven, transferred and rotated by 90°, the system transfers and stacks tiles horizontally onto the automatic feeding conveyor of the linear polishing machine.

Coupled with the Automatic Feeder/Tilter Mod. OM/AR-2, that also operates the overturning (180°) of the tile, allows the realization of an automatic supply line for polishing that easily fits all linear polishing machines increasing productivity and reducing the labor costs.

Technical Features

Automated robotic system for the discharge of cured tiles:

The production capacity is approximately 4/5 cycles per minute;

The overall weight is about 2.850 Kg;

The installed power is 9,3 kW (with OM/AR-2).