Our constant commitment to develop and improve our machines also goes through the research for special materials, which allow better performance and durability of each component.

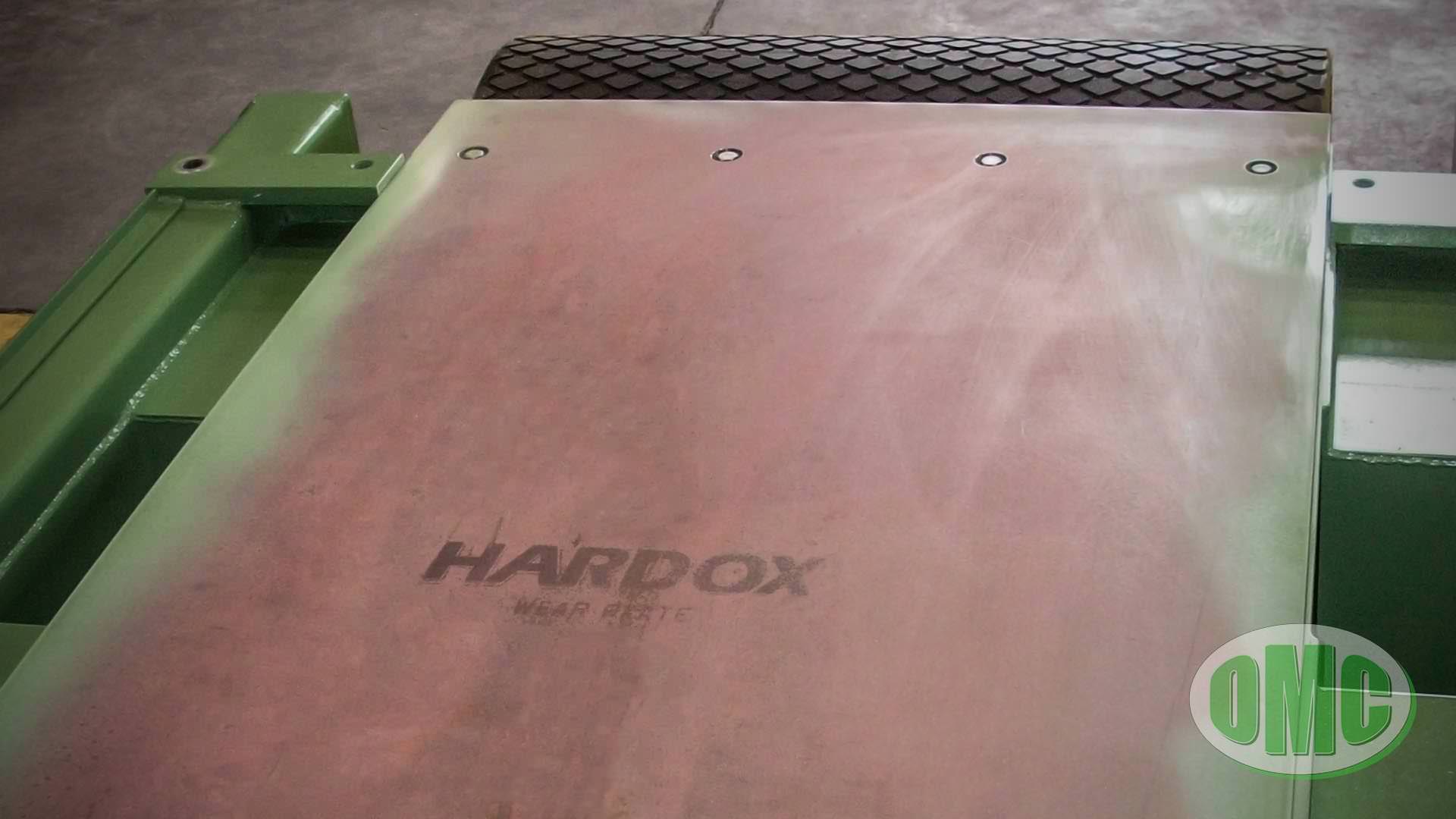

Excellent examples are the various parts subject to wear due sliding or rubbing, such as the sliding surfaces of our OM800 Series Linear Polishing/Honing Machines or the several components subject to wear and tear of our Dosers and Mixers: to improve the yield and allow a longer duration is used HARDOX® Anti-Wear Steel, material that combines hardness and toughness for high reliability of the components made.

Special steel made specifically to resist wear and rubbing, thanks to a hardness far superior to normal construction steels: the Hardox® wear plate is the most resistant steel in the world in terms of abrasion.

A peculiar feature is the extreme hardness, from the surface to the core, which allows to obtain long lasting components, improving the overall performance of the machine and reducing the need for spare parts.

To better understand the qualities of this special steel, below you can see a resistance test that compares a sheet of Hardox with a thickness of 5mm, with two sheets of steel S355, one of which 5mm and one of 12mm.